Electronic control unit for gas leak detection with 4 detection zones

-

DESCRIPTION

General features0

Electronic control unit for gas leak detection in industrial environment, suitable for controlling and signaling dangerous gas concentration in the air, specifically for detecting methane gas, LPG and carbon monoxide.

- Light signals: 1 red LED, power supply on, 1 yellow LED, general failure; 4 yellow LED, failure for each probe series; 4 red LED, gas alarms for each probe series.

- Acoustic signals: 1 buzzer with sound intensity > 60db at 1m.

- 1 button to reset the alarms and for testing the probes.

- Self-extinguishing plastic housing.

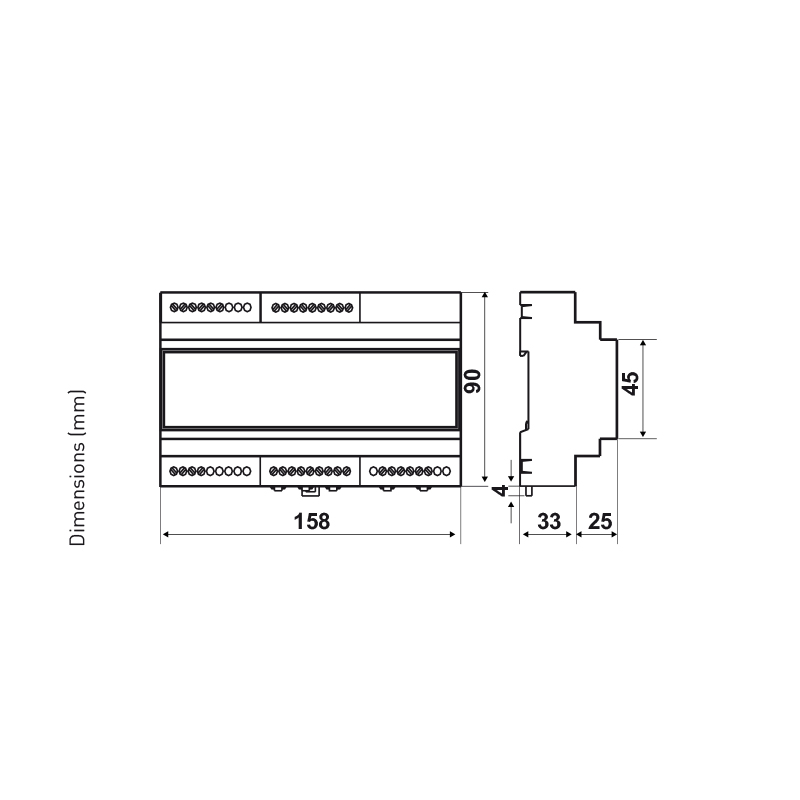

- Dimensions: 158 x 90 x 58 mm – 9 modules complies with DIN 43880 standard.

- Unit weight: 0.25 kg.

- Rear panel mounting on Omega DIN EN 50022 rail.

- Protection: IP20; IP40 when is properly installed in an electrical box.

- Environment temperature: 0 ÷ 50 °C.

- Environment humidity ±90% U.R. without condensation.

Electric features- Power supply: 12Vac/dc ± 10%.

- Absorption with 1 probe approximately 160mA (320mA).

- Absorption with 4 probes approximately 280mA (920mA).

- Connection with 2 terminals of 2.5 mm².

- Input – fuse power supply 1A 5x20mm.

- 4 inputs for sensors S81, S82, S83, or probes ATEX S84, S85, S86 (different gas types).

- Connection to the probe with 3 terminals of 2.5 mm², for each probe: C (-12…24V); S (+4…20mA); A (+12…24V).

- Maximum connection length 50 m, for each probe.

- Section of 3 conductors: 1.5 mm².

- Alarm output: n.1 relay with 1 SPDT contact 8A 250Vac.

- Failure output: n.1 relay with 1 SPDT contact 8A 250Vac.

- Outputs connections: n.3 terminals of 2.5 mm² for relay C-NC-NO.

-

ADVANTAGES

0

Electronic control unit for gas leak detection in industrial environment, suitable for controlling and signaling dangerous gas concentration in the air, specifically for detecting methane gas, LPG and carbon monoxide.

Advantages -

TECHNICAL SPECIFICATION

CODE POWER SUPPLY CONTACTS RATING CONNECTED SENSORS OPERATING AMBIENT TEMPERATURE PROTECTION DEGREE P82 12Vac/dc ± 10% 8A - 250V 4 - 10 ÷ 50 °C IP40 -

HOMOLOGATION AND INSTALLATION

Homologation

- Complies with the standards EN 61779-1-4; CEI 216-5/1; EMC 89/336/CEE; EN 50270

Installation and use- Rear panel mounting on Omega DIN EN 50022 rail.

- It can be installed on the bottom panel or DIN modular panels.

- To ensure the proper protection degree of the device is necessary to install the unit in an electric box created according to current regulations for the workplace and within which can also be housed the power supply system.

- P82 control unit allows you to connect up to 4 probes of model S81-82-83 or ATEX S84, S85, S86 probes for the construction of gas detection systems in environments such as boiler rooms, garages, warehouses, workshops, etc.. with the possibility to control a solenoid valve or an auxiliary device (siren, flashing light, extractor, etc..) through inside alarm relay.

- The installation of a gas leak detection system or the presence of carbon monoxide, do not exempt from compliance with all rules for installation and use of gas appliances and from the corresponding safety standards and law in force for this type of systems.

- The control unit must be powered at 12 Vac/dc.

- To connect the relay outputs use cables with a minimum section of 1.5 mm².

- The operation logic, selected by means of jumper E1, can be either positive or negative.

- The device reports its operation status through the LED.

ACCESSORIES

- S81: Sensor for methane gas detection.

- S82: Sensor for LPG gas detection.

- S83: Sensor for carbon monoxide detection.

- S80: Emergency signaling device with fixed light and continuous sound.

- S84: Probe for methane gas detection, certified with ATEX II 2G Ex d IIC T6.

- S85: Probe for LPG gas detection, certified with ATEX II 2G Ex d IIC T6.

- S86: Probe for carbon monoxide detection, certified with ATEX II 2G Ex d IIC T6.

- ZD… : Normally closed electromagnetic valves, with quick closing and opening, class a with approval.

- TECHNICAL LITERATURE

-

FAQS